In a recent conversation, David Kankaras, Senior Principal at Stantec, shared insights into how Stantec’s work in engineering and architecture is helping Ontario’s manufacturing sector address critical challenges and embrace new opportunities. With extensive global experience in designing advanced manufacturing facilities, Stantec brings valuable lessons to Ontario’s industry, helping it remain competitive and forward-looking.

Mercedes-Benz Canada Inc. - Fuel Cell Stack Manufacturing Clean Room, Burnaby, BC

Ontario’s manufacturing sector is navigating an increasingly competitive landscape, and Stantec’s involvement is focused on equipping local facilities with innovative, future-proofed designs. “Our multidisciplinary team works on complex manufacturing facilities worldwide, bringing lessons from those projects here,” Kankaras explains. “Being a Canadian firm with a strong Ontario presence, we take our broad expertise and apply it locally to help drive innovation and position the province as a leader in advanced manufacturing facilities.”

Ontario’s manufacturers face unique hurdles, including high capital costs, skilled labour shortages, and supply chain disruptions. Kankaras sees these challenges as defining the current moment: “Capital is a significant factor in creating these facilities—they’re complex and expensive. Additionally, there’s a shortage of skilled labour needed for construction, and we’re still seeing supply chain delays for key pieces of equipment.”

“Ontario has been on the right path, attracting key players that boost the local economy. We need to stay on this trajectory, making sure we communicate project timelines effectively and keep the design and construction industries ready for what’s coming.”

— David Kankaras, Senior Principal, Stantec

Stantec’s approach includes utilizing advanced modeling and simulation to address common issues before they occur on-site. “We implement complex models in our designs so that there are fewer clashes and better integration of all systems,” Kankaras says. “By ensuring that designs are ‘clash-free,’ we minimize potential conflicts and significantly reduce the cost of getting these facilities off the ground.”

Digital solutions are a cornerstone of this proactive approach, enabling Ontario’s manufacturers to remain agile and reduce delays. “These models integrate every piece of equipment that manufacturers plan to use, ensuring fewer on-site adjustments and avoiding costly schedule changes,” Kankaras emphasizes. “It’s about making sure manufacturers have the tools to meet global standards efficiently and cost-effectively.”

Keeping up with environmental standards is essential, and Stantec’s local knowledge allows them to guide manufacturers through regulatory processes without project delays. “We have a robust environmental engineering practice and work closely with manufacturers to complete assessments proactively,” Kankaras notes. “By advising on timelines and being proactive, we make sure projects meet regulatory needs without impacting their schedules.”

Sustainability remains a core part of Stantec’s approach. “Sustainability is always at the forefront,” Kankaras explains. “For instance, we completed a project recently that used only electric equipment, achieving a zero-carbon footprint and aligning with the client’s sustainability goals.” This example highlights Stantec’s commitment to integrating sustainable technologies that not only comply with regulations but also enhance long-term environmental performance.

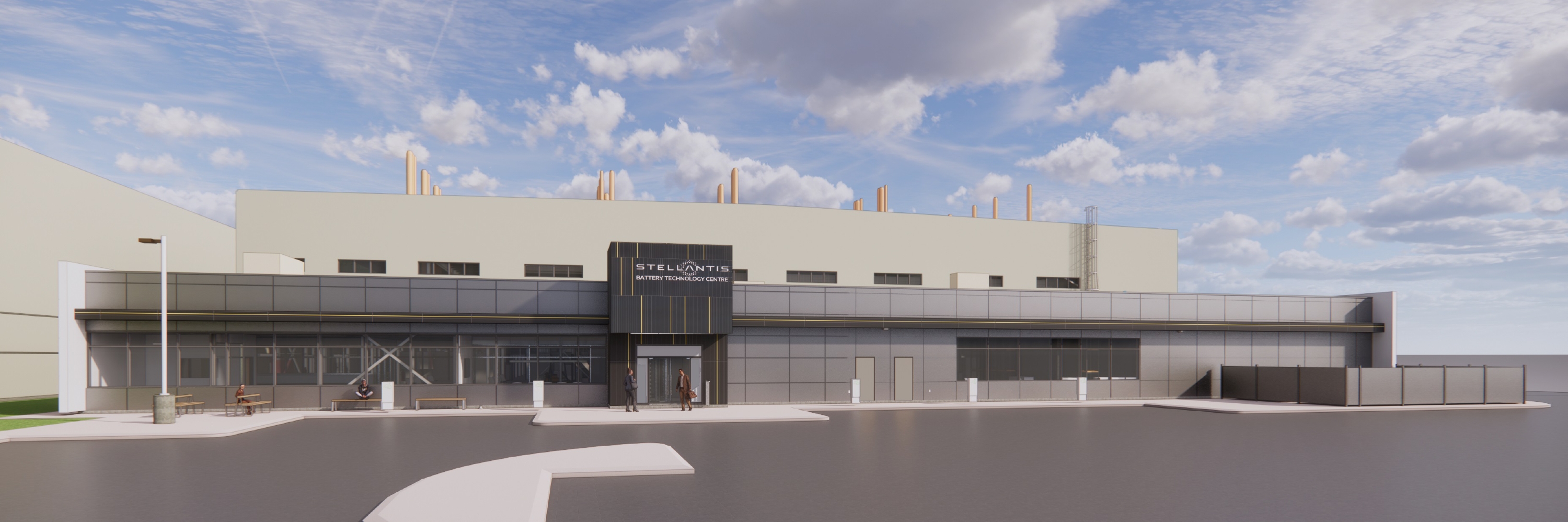

Stellantis Battery Testing Facility, Windsor, ON

Stantec’s regional presence enables them to work closely with manufacturers, staying connected to specific needs and regional nuances. “Being local helps us understand all the codes and jurisdictions,” says Kankaras. “Having completed many projects here in Ontario, we can accurately advise on timelines and navigate any regulatory requirements that arise.” Stantec’s multiple Ontario offices allow them to be close to project sites, offering on-the-ground support when needed and enhancing collaboration with local manufacturers.

E-One Moli Lithium-Ion Battery Cell Manufacturing Facility, Maple Ridge, BC

Ontario’s recent moves to attract major global players in battery production, like Stellantis, Volkswagen, and potentially Honda, are an encouraging sign for the province’s manufacturing landscape. “Ontario has been on the right path, attracting key players that boost the local economy,” says Kankaras. “We need to stay on this trajectory, making sure we communicate project timelines effectively and keep the design and construction industries ready for what’s coming.”

With Stantec’s focus on bringing advanced design and engineering practices to Ontario’s manufacturers, Kankaras believes the sector is well-positioned to compete globally. “The future is bright,” he reflects. “Stantec will be at the forefront, designing facilities that not only drive change but also support the right behaviours in the industry.”

By harnessing global expertise, digital technology, and sustainable practices, Stantec is helping Ontario’s manufacturing industry remain resilient and adaptable in a shifting global market. As Kankaras notes, the work is about more than just design; it’s about creating a robust foundation for Ontario’s economic future.

The Makers & Movers in Manufacturing series highlights our members who are at the forefront of Ontario’s manufacturing evolution. As advanced manufacturing gains momentum globally, the Toronto region stands poised to lead—powered by organizations pushing boundaries in innovation, technology, and sustainable production. This series celebrates the industry champions driving Ontario’s manufacturing sector toward resilience, competitiveness, and global leadership in next-generation manufacturing.