WSP in Canada, a global leader in engineering and professional services, employs over 13,000 people across the country. Renowned for its multidisciplinary expertise, the firm delivers innovative solutions across infrastructure, transportation, and environmental science. In manufacturing, WSP combines global experience with local insight to help clients tackle complex challenges while advancing efficiency, sustainability, and resilience.

Danny Rosanova, Vice-President of Regional Strategic Growth and Business Development at WSP in Canada, shared how the company’s practices are transforming Ontario’s manufacturing sector. With 13 years at WSP, Rosanova has seen firsthand how its innovation, global expertise, and sustainability focus are driving the industry forward.

WSP’s strength lies in its ability to deliver end-to-end project solutions. From initial site assessments to final commissioning, WSP’s multidisciplinary teams integrate environmental, transportation, and infrastructure expertise to create manufacturing facilities that are functional, resilient, and efficient.

“Our environmental team, for instance, can perform due diligence services such as geotechnical studies, hydrology assessments, and biodiversity integration,” Rosanova says. “This early involvement allows us to create more resilient structures and reduce carbon impacts while seamlessly integrating projects into their ecosystems.”

This holistic approach extends to transportation solutions as well. WSP evaluates options including road, rail, marine, and air access to optimize the movement of people and goods to and from manufacturing sites, ensuring clients can transport products efficiently while meeting regulatory requirements.

Anticipating change lies at the core of WSP’s “Future Ready” approach, a principle guiding the firm’s design philosophy.

“We’re designing facilities that might serve a company for 40 to 60 years,” Rosanova explains. “To do this effectively, we embed flexibility into the structure and systems to accommodate innovations in equipment and processes.”

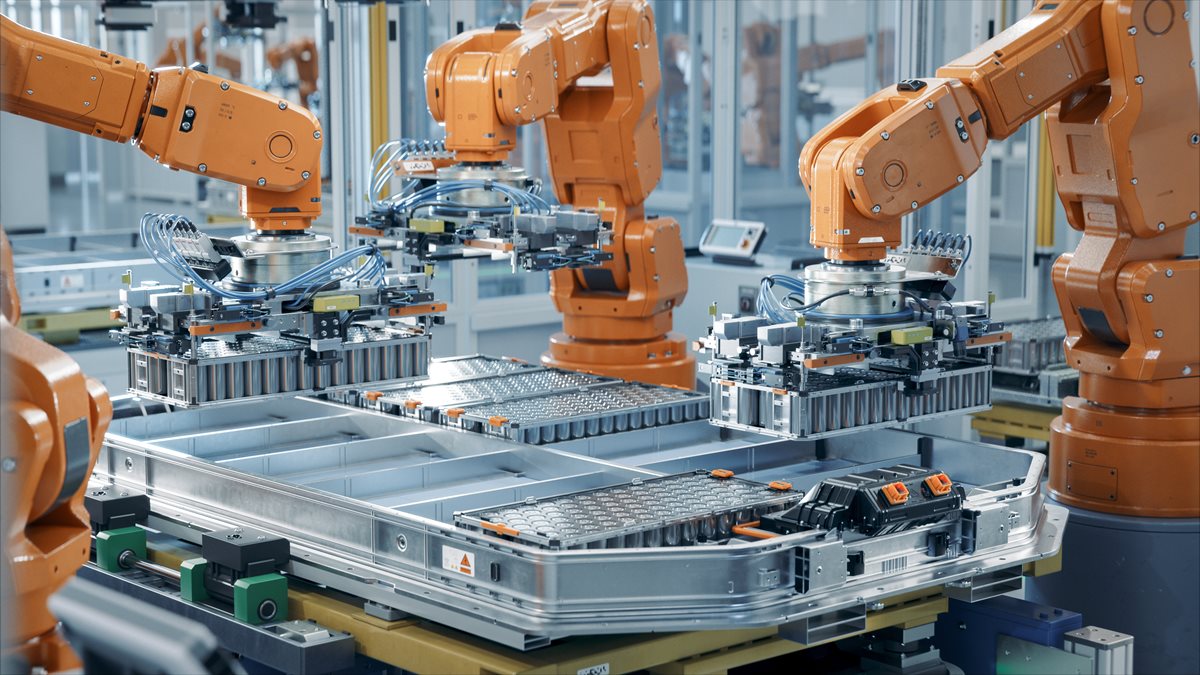

This philosophy is exemplified in WSP’s work with battery manufacturing facilities, where rapid technological advancements demand adaptable designs. By incorporating flexibility into their facilities, WSP minimizes costly retrofits and ensures long-term functionality.

Innovation is central to WSP’s ability to stay ahead of industry trends. The firm leverages artificial intelligence (AI) to optimize engineering workflows and employs predictive modelling to bolster supply chain resilience.

“With AI combined with the great expertise of our engineers and scientists at WSP, we can generate almost unlimited design options and identify the most optimal solutions for our clients,” Rosanova says. “This also enables us to conduct critical analyses, such as embodied carbon and supply chain optimization, earlier in the process, helping clients reduce costs and improve efficiency.”

“What excites me most is the role WSP plays in addressing society’s biggest challenges. Whether it’s supporting EV supply chains, enhancing transit infrastructure, or ensuring sustainable development, our work is truly about building a better future.”

– Danny Rosanova, VP of Regional Strategic Growth & Business Development, WSP in Canada

WSP’s ability to blend global best practices with local expertise sets it apart in Ontario’s manufacturing sector. By leveraging its extensive network of experts, the firm ensures its solutions are tailored to the region’s unique needs.

“Take the Volkswagen PowerCo battery plant in St. Thomas, Ontario,” Rosanova notes. “We brought in global experts from the UK and South Africa with experience in stringent clean and dry room standards. This collaboration ensured we delivered the best solutions tailored to the client’s needs.”

Through its global reach and local focus, WSP enables Ontario’s manufacturers to benefit from cutting-edge solutions, positioning the region as a leader in advanced manufacturing.

As Canada’s largest environmental consulting firm, WSP helps manufacturers integrate sustainability into their operations while enhancing competitiveness. From energy modelling and renewable energy integration to lean manufacturing and EV infrastructure design, WSP delivers strategies that meet regulatory requirements and exceed industry standards.

“We guide our clients toward eco-friendly practices that reduce waste and operational costs while boosting brand reputation,” Rosanova says. “In many cases, these solutions not only pay for themselves but yield long-term value.”

WSP also excels in supply chain optimization, helping manufacturers enhance efficiency and plan for growth. By using techniques like value stream mapping and discrete event simulation, the firm identifies opportunities for improvement across processes and systems.

“A common misconception is that expanding capacity always requires expanding facilities,” Rosanova explains. “Often, the first step should be to optimize existing processes. This not only boosts current production but also informs smarter expansion decisions.”

By focusing on sustainability and supply chain optimization, WSP ensures manufacturers remain competitive in a global market while achieving operational efficiency and environmental goals.

Looking ahead, WSP remains committed to addressing the significant challenges facing Ontario’s manufacturing sector, from decarbonization and clean energy transitions to fostering a regulatory environment that supports innovation.

“What excites me most,” Rosanova reflects, “is the role WSP plays in addressing society’s biggest challenges. Whether it’s supporting EV supply chains, enhancing transit infrastructure, or ensuring sustainable development, our work is truly about building a better future.”

With its multidisciplinary expertise, commitment to sustainability, and innovative culture, WSP is not just a partner to manufacturers but a driving force in shaping Ontario’s manufacturing landscape for decades to come.